Inductive Rechargeable Flameless Candles: A Synthesis of Innovation and Manufacturing Prowess

Core Knowledge of Inductive Rechargeable Flameless Candles

The Inductive Rechargeable Flameless Candles represent a significant advancement in ambient lighting, blending solid-state electronics with the aesthetic appeal of traditional candlelight. This product category addresses both safety concerns associated with open flames and the sustainability challenge posed by disposable batteries.

Inductive Charging Technology: The foundational element is electromagnetic induction, which facilitates wireless power transfer (WPT). The candles utilize a receiver coil within their housing to capture energy from an AC magnetic field generated by a dedicated charging base (transmitter coil). This process eliminates the need for direct metallic contact (such as charging ports or exposed terminals), enhancing water resistance and simplifying the charging procedure for the end-user. The absence of physical wear points contributes to the product's longevity and reliability.

LED Light Source and Flame Simulation: The candles employ Light-Emitting Diodes (LEDs), specifically chosen for their high luminous efficacy and extended operational life. Sophisticated internal circuitry is dedicated to flicker emulation, modulating the LED's output to mimic the stochastic movement and color temperature shift of a burning wick. This is often achieved through pulse-width modulation (PWM) techniques combined with tailored diffuser optics to scatter the light, creating a convincing, dynamic, and soft glow.

Energy Management and Battery System: The "rechargeable" aspect is rooted in an integrated secondary battery cell (typically Lithium-ion or NiMH, depending on design parameters) coupled with a Battery Management System (BMS). The BMS ensures optimal charging cycles, protecting against overcharge, over-discharge, and thermal runaway, which are critical factors for product safety and maintaining the capacity retention over thousands of charging cycles.

Material Science and Housing Design: The exterior casing, often composed of high-grade thermoplastics or polymeric materials, is engineered not only for aesthetic purposes (e.g., simulating wax texture) but also for durability and heat dissipation. The design must accommodate the optical requirements of the LED and the spatial constraints of the internal electronics (receiver coil, PCB, battery).

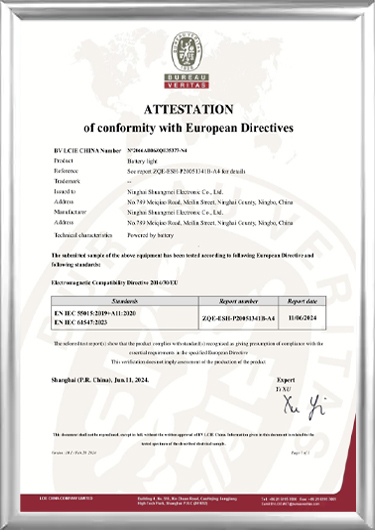

The successful large-scale manufacture and market deployment of the 4 Pack White Inductive Rechargeable Flameless Candles are directly supported by the operational scale and manufacturing efficiencies of Ninghai Shuangmei Electronic Co., Ltd.

Scaled Production and Supply Chain Synchronization: The stated capacity of 6 production lines delivering 10,000 units daily signifies a highly optimized and structured manufacturing environment. This scale is crucial for meeting the demands of high-volume markets. The management of raw materials—including specialized LED chips, WPT components, battery cells, and custom-molded housings—requires sophisticated Supply Chain Management (SCM) to ensure a steady, high-quality input flow commensurate with this significant daily output.

Manufacturing Process Flow: The integration of components for this product demands expertise across multiple manufacturing disciplines: Printed Circuit Board Assembly (PCBA) for the control and charging electronics, Solder Reflow Processes, Battery Integration, and Precision Component Placement for the LED and sensor elements. The high-volume output suggests a strong reliance on lean manufacturing principles and potentially automated assembly stations to maintain quality consistency across the entire production run.

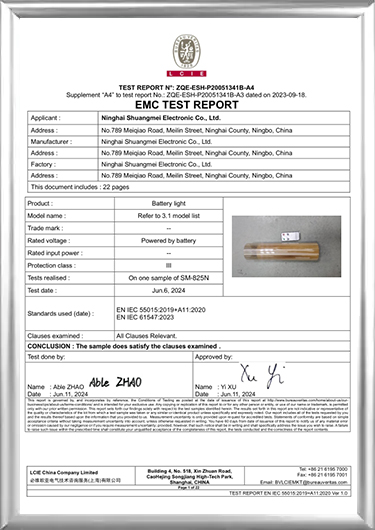

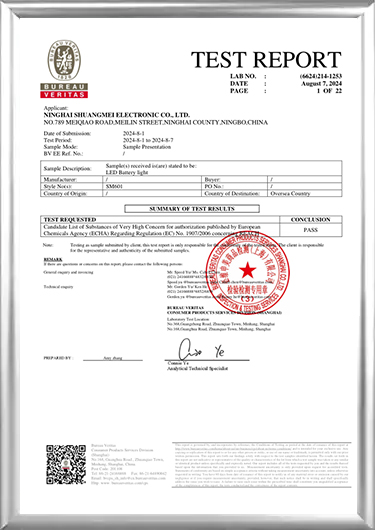

Quality Assurance Framework: With such a high daily volume, a robust Quality Management System (QMS) is indispensable. The focus shifts to in-line quality checks and Statistical Process Control (SPC) to monitor critical parameters—such as the inductive coupling efficiency, LED luminance stability, and battery pack performance—at every stage of the 6 production lines, ensuring that the final product adheres to strict electromagnetic compatibility (EMC) and safety standards.

Manufacturing and Product Lifecycle Overview

| Feature Category |

Description (Knowledge-Based Focus) |

Operational Implication for Shuangmei |

| Power System |

Sealed, integrated, induction-enabled power unit for continuous, safe recharge. |

High-volume integration of coils, BMS, and battery cells; critical for safety testing. |

| Illumination System |

Utilizing high-efficiency LEDs with advanced optical diffusers and PWM for dynamic flicker. |

Precision mounting of surface-mount devices (SMD LEDs) and customized tooling for housing optics. |

| Ergonomics & Design |

Housing materials selected for aesthetic realism and durability against environmental factors. |

Expertise in injection molding of complex polymer geometries and material science application. |

| Product Lifespan |

Determined by the longevity of the LED source and the cycle life of the rechargeable battery. |

Strict control over component sourcing and assembly quality to guarantee advertised operational hours. |

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of inductive charging in this application over traditional wired charging?

A: The core benefit lies in hermetic sealing and operational resilience. By eliminating external metal contacts or charging ports, the product achieves superior protection against moisture ingress and corrosion, which is critical for decorative lighting often used in diverse environments. Furthermore, it simplifies the user experience and reduces potential physical wear-and-tear associated with repeatedly plugging and unplugging a cable.

Q2: How is the 'flickering' effect achieved electronically, and why is it important?

A: The realistic flicker is accomplished through microcontroller-driven Pulse-Width Modulation (PWM). The duty cycle of the LED current is rapidly and pseudorandomly adjusted to create variations in brightness. This is vital as it satisfies the psycho-visual expectation of traditional candlelight, enhancing the product's ambient realism and market acceptance over a static LED light source.

Q3: What role does the BMS play in the rechargeable flameless candle system?

A: The Battery Management System (BMS) is the electronic supervisor of the energy cell. It is responsible for monitoring parameters like voltage, current, and temperature during both charging and discharge cycles. Its key function is to prevent conditions that could compromise battery integrity, such as deep discharge or thermal overload, thereby maximizing the battery's cycle life and ensuring the overall safety and reliability of the product.

Q4: Given Ninghai Shuangmei's high-volume capacity, what does this imply for quality control?

A: The daily output of 10,000 units necessitates a shift from batch inspection to proactive, continuous quality monitoring. It implies the implementation of automated testing fixtures and a rigorous in-process defect detection system across all 6 production lines. The focus is on zero-defect methodology at the component level to prevent bottlenecks and maintain the consistency required for high-volume delivery.

Q5: What are the main factors contributing to the product's operational lifespan?

A: The lifespan is primarily dictated by two electronic components: the LED emitter and the rechargeable battery. The LED's life is measured by the time until its luminous output degrades to a specified percentage (e.g., L70). The battery's life is measured by its cycle count before its capacity falls below a functional threshold. The design must manage both the thermal stress on the LED and the electrical stress on the battery for maximum operational duration.

English

English

Español

Español