The landscape of decorative lighting has been significantly transformed by the advent of flameless candle technology, offering an appealing blend of aesthetic warmth and enhanced safety. The Set of 3 Red Flameless Pillar Candles with Remote represents a prime example of this evolution, embodying advanced electronic design principles tailored for home and event decor.

I. Core Technological and Design Considerations

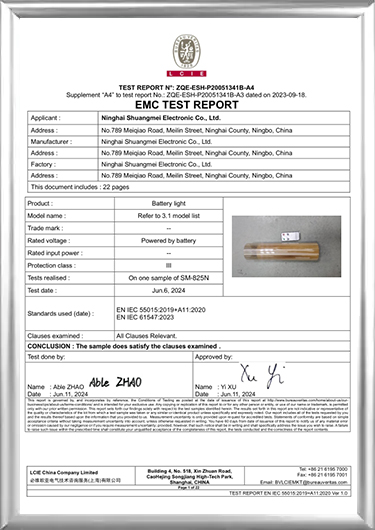

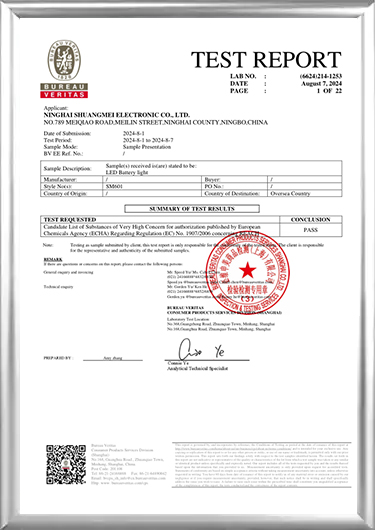

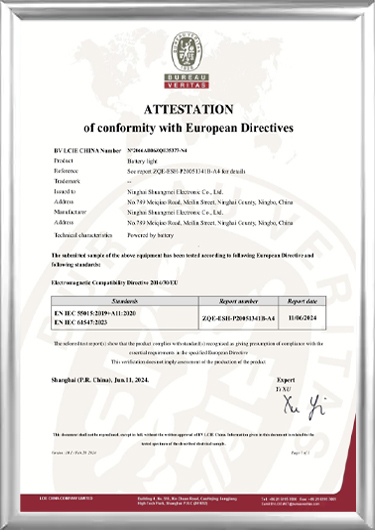

The development and manufacturing of products like the Set of 3 Red Flameless Pillar Candles involve specialized knowledge in materials science, LED technology, and integrated circuit design, areas where dedicated manufacturers like Ninghai Shuangmei Electronics Co., Ltd. leverage their operational expertise.

Illumination Mechanism: The core function relies on low-power, high-efficiency Light Emitting Diodes (LEDs). These LEDs are selected and configured to emit a specific wavelength range, carefully calibrated to reproduce the warm, deep red glow traditionally associated with wax candles, maximizing visual fidelity while minimizing energy consumption.

The Flameless Effect: Achieving the illusion of a flickering flame is a complex engineering task. This involves sophisticated microchip programming to generate pseudo-random fluctuations in LED intensity. This non-repeating, dynamic light pattern is crucial for replicating the natural, unpredictable movement of an actual flame, thereby enhancing the realistic ambiance.

Pillar Construction and Durability: The outer shell, often a high-grade plastic polymer or real wax coating, is engineered for both aesthetic appeal and structural integrity. The design ensures the housing effectively diffuses the internal LED light, scattering it evenly to create a soft, omnipresent glow, while also providing robust protection for the sensitive internal electronic components.

Remote Control Integration: The inclusion of a remote control system demands precision in infrared (IR) or radio frequency (RF) signal transmission and reception. The electronic control board within the candle must be designed to reliably interpret diverse commands—such as power cycling, timer setting, and mode selection—ensuring instantaneous and consistent user interaction across all three units simultaneously.

Power Management System: These devices are typically battery-powered, necessitating an optimized circuit design to maximize operational lifespan. The system must efficiently manage power draw, especially during the dynamic 'flicker' mode, to strike a sustainable balance between light output intensity and extended battery life, a critical factor for end-user satisfaction.

II. Quality Assurance and Production Synergy with Ninghai Shuangmei Electronics Co., Ltd.

A comprehensive understanding of manufacturing excellence is what allows a producer to consistently deliver a high-quality product. The manufacturing process for this specialized set of candles underscores the strategic importance of a disciplined quality management framework, which is central to the operational ethos of companies like Ninghai Shuangmei Electronics Co., Ltd.

Raw Material Vetting: The reliability of the final product begins with rigorous qualification of input materials. This includes the LEDs, the specific polymers used for the housing, the composition of the printed circuit boards (PCBs), and the quality of the battery contacts. Only materials meeting stringent performance and longevity criteria are integrated into the production chain.

Process Control in Assembly: The assembly of the electronic core—which involves soldering the LED to the PCB, integrating the microchip, and connecting the power leads—is subject to strict, monitored procedures. Consistency in these critical steps is paramount to prevent early failure and ensure uniform performance across the entire set.

Electro-Optical Calibration: Each finished candle undergoes specialized testing to verify its light output characteristics. This involves confirming the correct chromaticity (color temperature), intensity level, and the randomness of the flicker pattern, guaranteeing that the aesthetic goals of the red color and realistic movement are fully achieved.

Structural and Functional Audits: The final inspection stage involves comprehensive checks on physical durability and remote control functionality. This assures that the exterior finish is flawless and that the remote signals are reliably received and acted upon by each of the three candles, validating the complete user experience.

III. Product Knowledge Matrix: Key Functional Areas

| Component/Function |

Description of Operational Principle |

Importance in Product Context |

| LED Emitter |

Solid-state semiconductor device engineered for deep red light spectrum emission. |

Ensures high energy efficiency and consistent color rendering over long periods. |

| Microcontroller Unit (MCU) |

Small integrated circuit responsible for executing the programmed lighting sequence and interpreting remote commands. |

Governs the realistic, non-periodic 'flicker' effect and manages timer settings. |

| Outer Casing Material |

Real wax blend or durable, light-diffusing thermoplastic polymer. |

Provides the aesthetic form factor and ensures uniform light transmission/diffusion. |

| Infrared (IR) Receiver |

Photodiode component sensitive to the specific IR wavelength emitted by the remote transmitter. |

Facilitates non-contact control over power, mode, and timing functions. |

| Battery Compartment |

Engineered contact points and housing for standard power cells (e.g., AA or AAA). |

Crucial for reliable power supply and maintaining electrical continuity under various operating conditions. |

Frequently Asked Questions (FAQ) on Flameless Pillar Candle Technology

Q1: How is the 'Set of 3' configuration standardized for synchronized control?

A1: The synchronization relies on an identical and robust IR or RF receiver and MCU programming across all three pillar units. When the remote control transmits a command (e.g., 'Power On' or 'Timer 6H'), the signal is broadcast. Each candle's receiver simultaneously picks up the signal and executes the identical command, ensuring that the entire set operates in unison from a single input.

Q2: What is the principal difference in illumination quality between LED flameless candles and traditional filament-based electric candles?

A2: LED flameless candles utilize the intrinsic benefits of solid-state lighting: superior energy efficiency, significantly longer operational life, and minimal heat generation. Crucially, the light spectrum emitted by modern, specialized LEDs can be precisely controlled for chromaticity, allowing for a more authentic and warmer 'red' light rendering compared to the often harsh, fixed light of older filament bulbs.

Q3: How does the quality management focus of a direct producer, such as Ninghai Shuangmei Electronics Co., Ltd., influence cost-effectiveness?

A3: A direct producer with a robust quality management system achieves cost-effectiveness not through compromise, but through efficiency and waste reduction. By strictly controlling the quality of raw material inputs and minimizing in-process defects, the manufacturer reduces the need for costly rework, limits the volume of scrapped products, and ensures a higher first-pass yield, ultimately translating into a more competitive product offering without sacrificing intrinsic quality.

Q4: What are the main benefits of utilizing an electronic timer function in the flameless candle design?

A4: The electronic timer, typically managed by the internal MCU, is a critical power-saving and convenience feature. It eliminates the need for manual power-cycling and prevents batteries from being inadvertently drained. The user can set a specific operating duration (e.g., 4 or 8 hours), after which the circuit automatically cuts power, ensuring the maximum extension of battery life and maintenance of a consistent decorative schedule.

Q5: What are the engineering challenges associated with the 'flicker' effect in the red pillar candles?

A5: The challenge lies in creating a randomized, natural-looking fluctuation that does not appear overtly cyclical or mechanical. Engineers must program the MCU with an algorithm that governs rapid, subtle, and non-repeating variations in the current supplied to the LED. The chosen red color also requires fine-tuning of the current modulation to ensure that the perceived warmth and richness of the color remain consistent even as the intensity shifts.

English

English

Español

Español