Birch Bark Illumination: Integrating Aesthetics and Expertise

The market for sophisticated, ambient lighting solutions is consistently driven by the fusion of natural aesthetics and modern technology. Within this specialized sector, the Set of 3 Birch Bark Battery Operated Pillar Candles represents a significant category, embodying a commitment to both visual fidelity and functional safety. This product line, characterized by its authentic textural finish and core electronic components, offers a unique proposition for consumers seeking warmth without the inherent risks of open flame.

The successful realization of this particular product category hinges on a meticulous process that transforms conceptual design into a tangible, high-quality decorative item. This developmental journey is where the specialized capabilities of a manufacturer like Ninghai Shuangmei Electronic Co., Ltd. become critical.

Key Knowledge Domains of the Birch Bark Pillar Candle Category

The production and market positioning of the Set of 3 Birch Bark Battery Operated Pillar Candles involve several interconnected knowledge areas that underscore its complexity and value.

Aesthetic Material Science and Emulation:

The primary challenge lies in the faithful replication of natural birch bark texture and coloration. This requires expertise in polymer science and molding techniques to achieve a tactile and visual surface that convincingly mimics the organic source material.

Emphasis is placed on achieving a "true-to-nature" finish, encompassing subtle variations in pattern and hue, which differentiates premium products from generic alternatives.

The choice of outer casing material is also crucial for durability, light diffusion properties, and resistance to environmental factors.

Integrated Circuitry and Power Management:

The core functionality relies on a carefully designed low-voltage LED system. Knowledge of optimal current regulation is essential to maximize battery life while maintaining consistent light output and color temperature.

The integration of timer functions, remote control compatibility, or various flicker modes necessitates sophisticated micro-controller programming and reliable circuit board design.

Ninghai Shuangmei Electronic Co., Ltd.'s involvement in this phase, as highlighted by their focus on product design based on customer requirements, speaks to the critical importance of tailoring the internal electronics package to meet specific functional and performance benchmarks.

LED Light Source Characteristics:

The selection of the specific Light Emitting Diode (LED) governs the candle's ambiance. Products in this category typically employ warm-white LEDs with a color temperature carefully calibrated to mimic the glow of a traditional flame (often in the range of 2200K to 2700K).

Techniques for creating a convincing "flame effect," often involving movement mechanisms or specialized LED patterns, require continuous refinement in optoelectronics.

Design-for-Manufacture (DFM) and Specification Integrity:

The crucial initial stages of communication and design, where aspects like product size, shape, and color are finalized—as detailed by Ninghai Shuangmei Electronic Co., Ltd.'s pre-production protocol—are paramount. These details determine tooling requirements, assembly efficiency, and final unit cost.

Achieving the perfect cylindrical geometry for the pillar form factor, coupled with the application of the birch bark finish, demands precision in mold making and material handling.

The overall stability and balance of the product must be engineered to prevent tipping, ensuring consumer safety and satisfaction.

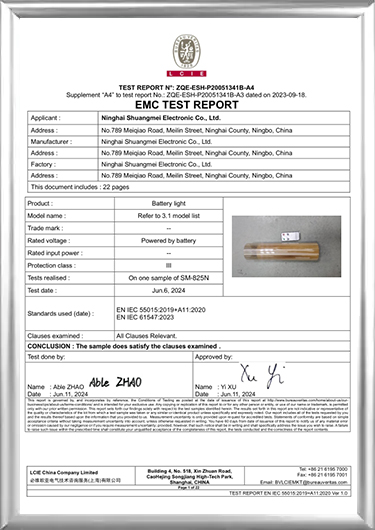

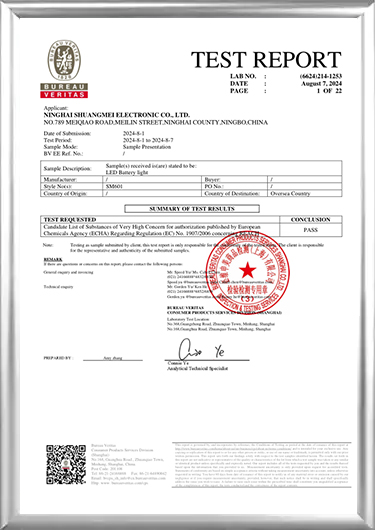

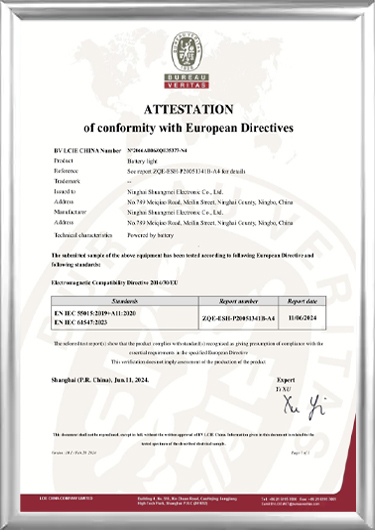

Safety and Regulatory Compliance:

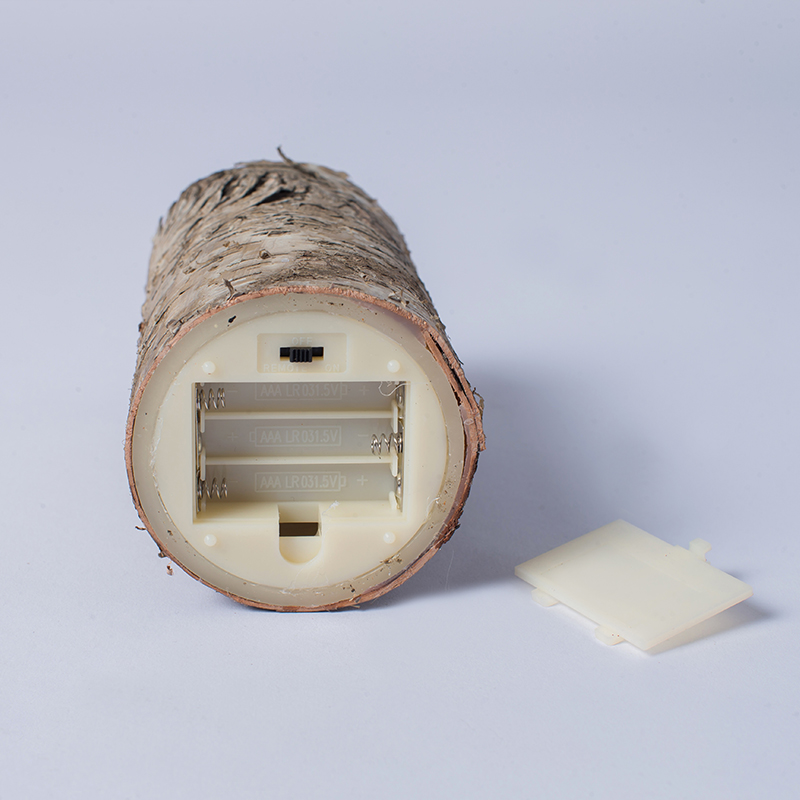

As battery-operated devices, these products fall under various international safety and electromagnetic compatibility (EMC) standards. Expertise in designing power compartments for secure battery insertion and isolation is non-negotiable.

The selection of materials must adhere to restrictions on hazardous substances, reflecting a commitment to global environmental and health standards.

Comparative Overview: Traditional vs. LED Birch Pillars

| Feature |

Traditional Birch Log Candle |

Battery-Operated Birch LED Candle |

| Light Source |

Combustible Wick |

LED (Light Emitting Diode) |

| Material Stability |

Wax melts and deforms over time |

Shell retains shape indefinitely |

| Safety Profile |

High risk (fire, heat damage) |

Safe (cool to touch, no combustion) |

| Placement |

Restricted (away from fabrics/shelves) |

Unlimited (bookshelves, lanterns, floral arrangements) |

| Longevity |

Single-use (burns down) |

Infinite (requires battery changes only) |

| Air Quality |

Emits smoke/soot |

Zero emissions |

Manufacturing and Customization Integration

| Product Element / Feature |

Manufacturing Focus Area (Ninghai Shuangmei Electronic Co., Ltd.) |

Outcome / Importance |

| Pillar Dimensions (Size, Shape) |

Customer Communication & Tooling Design: Precise translation of client-specified height and diameter into mold specifications. |

Ensures consistent form factor and fit within decorative settings; dictates material usage. |

| Bark Aesthetics (Color, Texture) |

Material Specification & Surface Treatment: Selection of base polymer and detailed process for achieving realistic birch finish. |

Defines the product's premium visual appeal and market differentiation. |

| Operational Modes (Timer, Flicker) |

Product Design & Electronics Engineering: Development and testing of the internal PCB and software logic. |

Provides core functional value and enhances user convenience; affects battery longevity. |

| Battery Housing |

Safety & Component Integration: Design for secure, accessible power cell placement and adherence to safety isolation protocols. |

Non-negotiable safety feature; impacts ease of use and long-term durability. |

Frequently Asked Questions (FAQ) on Birch Bark Pillar Candles

Q: What is the primary advantage of the battery-operated pillar candle design over traditional wax candles?

A: The core advantage is the decoupling of aesthetic warmth from fire hazard. The design provides a high degree of visual fidelity to a burning candle without requiring constant supervision, eliminating fire risks, smoke, soot, and melting wax, making it suitable for environments where open flames are restricted.

Q: How is the realistic "birch bark" surface effect achieved during production?

A: The authentic surface is typically achieved through a multi-stage process involving specialized molding techniques and, subsequently, a precise surface application or treatment. This often utilizes high-resolution molds replicated from natural bark samples to capture fine texture, followed by layered painting or polymer infusion to achieve depth and color variation.

Q: In the context of a manufacturer like Ninghai Shuangmei Electronic Co., Ltd., how does the initial customer communication on "color" affect the final product?

A: The specification of "color" goes beyond mere hue. It dictates the Color Rendering Index (CRI) and Color Temperature (CCT) of the internal LED. A manufacturer must ensure the LED's light output interacts correctly with the birch bark casing material to produce the desired warm, ambient glow, requiring careful component sourcing and calibration during the product design phase.

Q: What design elements contribute to the longevity and robustness of these electronic candles?

A: Longevity is ensured by selecting high-efficiency LEDs with long lifespans, optimizing the power management circuitry to reduce battery drain, and using durable outer casing materials that resist cracking or fading. Robustness is further achieved through internal structural design that securely anchors the electronic components against impacts.

Q: What is the significance of the "flame effect" mechanism, and what knowledge domain does it rely on?

A: The flame effect is a key feature distinguishing premium electronic candles. It relies on a delicate integration of mechatronics and optoelectronics, often involving a magnetically suspended or physically agitated small plastic element combined with a strategically positioned LED. Expertise in miniature motion systems and light diffusion is necessary to create a convincing, random, and naturalistic flicker.

English

English

Español

Español