The flameless taper candle represents a sophisticated evolution in decorative and functional lighting, skillfully merging the aesthetic appeal of traditional candlelight with the convenience and safety of modern electronics. This product category, central to the offerings of industry leaders like Ninghai Shuangmei Electronic Co., Ltd., embodies a commitment to both timeless design and cutting-edge quality control. The synergy between this elegant product and a manufacturing entity dedicated to stringent quality standards forms the basis of its market excellence.

Key Characteristics and Technology of Flameless Taper Candles

Flameless taper candles are defined by several core features and the underlying technology that replaces an open flame, making them ideal for diverse settings ranging from residential decor to large-scale event staging.

Illumination Mechanism:

Unlike traditional paraffin or wax tapers, flameless variants utilize an LED (Light-Emitting Diode) light source. This technology is prized for its exceptional longevity and minimal power consumption, contributing to a reduced need for frequent battery replacement and a longer product lifespan.

The light output is meticulously engineered to replicate the warm, soft glow and flickering motion characteristic of a burning wick. This is often achieved through proprietary algorithms and physical designs, ensuring a realistic visual effect without the inherent risks of fire.

Construction and Materiality:

The primary body is typically constructed from real wax or a high-quality wax-simulating polymer. This choice is crucial for achieving the authentic look and feel of a genuine candle, often featuring the classic slender, elongated form factor of a taper.

The internal structure houses the electronics, including the LED, the control circuit board, and the battery compartment, all precisely fitted to maintain the product’s sleek profile and structural integrity.

Operational Versatility and Control:

Flameless tapers frequently incorporate remote control capability, allowing users to manage multiple candles simultaneously for effortless setup and adjustment, particularly beneficial in hard-to-reach locations or large installations.

A common feature is the integrated timer function. This allows the candle to operate in pre-set cycles (e.g., 4 hours on, 20 hours off), promoting energy efficiency and automated use, enhancing their function as ambient lighting.

Safety and Environmental Profile:

The foremost advantage is the complete elimination of an open flame, soot, and dripping wax. This makes them universally safe for use around children, pets, textiles, and in environments where fire codes prohibit traditional candles.

The LED technology's energy efficiency aligns with modern sustainability principles, offering an eco-friendlier alternative to consumable wax candles.

The Role of Manufacturing Excellence: Ninghai Shuangmei Electronic Co., Ltd.

The sophisticated nature of the flameless taper candle—a blend of detailed aesthetic design and reliable microelectronics—demands a manufacturing partner with a demonstrable commitment to quality assurance. Ninghai Shuangmei Electronic Co., Ltd. provides this critical foundation, underpinning the market trust in its products.

Quality Assurance Framework

The company's ability to consistently deliver superior flameless candles is rooted in a comprehensive and multi-layered Quality Management System (QMS).

Internal Control Rigor:

The internal processes are characterized by strict, multi-stage control points throughout the entire production lifecycle, from component sourcing to final assembly.

The emphasis is placed on process stability and consistency, ensuring that the delicate balance between the electronic components and the aesthetic housing is maintained across every production batch. This internal scrutiny guarantees the longevity and performance of the LED mechanism.

External Validation and Compliance:

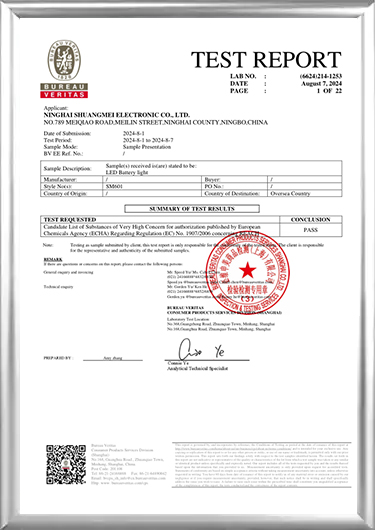

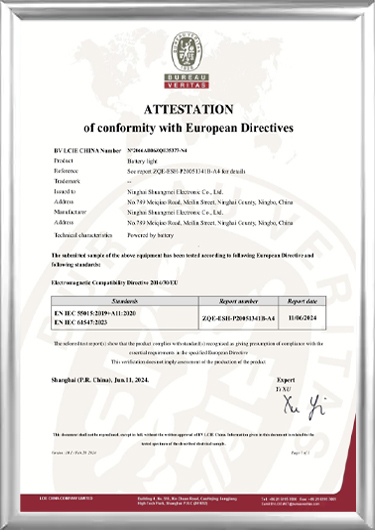

The company actively pursues and maintains high-level international certifications, which serve as independent verification of its operational integrity and product quality.

The possession of the BSCI certification reflects a commitment to ethical sourcing and responsible business practices beyond mere product performance.

Product Patent protection signifies investment in proprietary innovation, particularly in aspects relating to the realism of the flicker effect or the efficiency of the control systems.

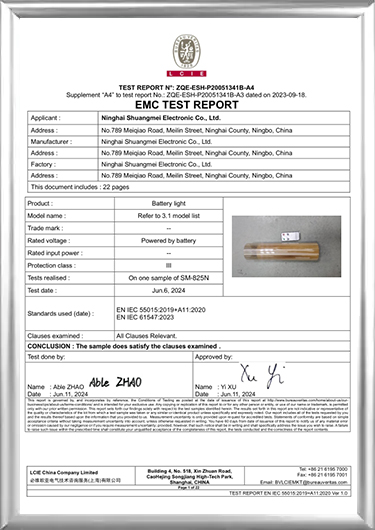

Essential international product compliance markings—including CE, ROHS, REACH, and EMC—demonstrate adherence to European standards for health, safety, and environmental protection, as well as the crucial assurance of Electromagnetic Compatibility for the integrated electronic components.

Technical Specifications and Operational Overview

Flameless Taper Candles are designed with specific operational parameters and performance metrics that define their utility and reliability.

| Aspect |

Description |

| Light Source |

Solid-state LED, specifically chosen for a low Color Temperature (CCT) to mimic natural candle warmth. |

| Power Source |

Typically small-form-factor dry-cell batteries, optimized for sustained low-current draw. |

| Control Interface |

Integrated On/Off switch at the base, often supplemented by Infrared (IR) remote control capability. |

| Flicker Simulation |

Microcontroller-driven randomized light intensity variation to replicate dynamic flame movement. |

| Housing Material |

Wax or ABS Polymer, treated for UV stability and durability. |

| Intended Use |

Ambient lighting, decorative accents, event table settings, and window lighting. |

Frequently Asked Questions (FAQ)

Q1: What is the primary safety benefit of using a flameless taper candle over a traditional one?

The core safety advantage lies in the complete absence of an open flame and heat. This eliminates the risk of fire, combustion, or accidental burns, allowing the candles to be placed safely near flammable materials, curtains, or in high-traffic areas without constant supervision.

Q2: How does the LED light source achieve a realistic "flicker" effect?

The realistic flicker is achieved through a microprocessor or dedicated integrated circuit within the candle's electronics. This component controls the power supplied to the LED, causing its intensity to randomly and subtly fluctuate. The best designs, like those backed by the robust quality controls of Ninghai Shuangmei Electronic Co., Ltd., use sophisticated programming to ensure the variation is non-repeating and visually organic.

Q3: What is the significance of the EMC certification for an electronic candle?

EMC (Electromagnetic Compatibility) certification is crucial as it verifies that the electronic components (the circuit board and LED) in the flameless candle do not emit levels of electromagnetic interference that could disrupt other electronic devices, and conversely, that the candle itself is resistant to typical electromagnetic interference from the environment. This ensures reliable operation when placed near other household electronics.

Q4: Are these candles generally resistant to typical indoor temperatures?

Yes. While they may be constructed of real wax, the operating temperature is significantly lower than that of a burning candle. High-quality flameless tapers, like those manufactured under the stringent quality system of Ninghai Shuangmei Electronic Co., Ltd., are designed to maintain their form and structural integrity in standard indoor environments, though prolonged exposure to direct, intense sunlight or extreme heat should generally be avoided to prevent softening of the wax casing.

Q5: Can these candles be used outdoors?

While they are inherently safer than open-flame candles, their electronic components and wax exterior are typically designed for indoor use. If intended for outdoor use, one must ensure the specific model is designated as weather-resistant or IP-rated to protect the electronics from moisture and humidity. Without such a rating, outdoor use is generally not recommended.

English

English

Español

Español